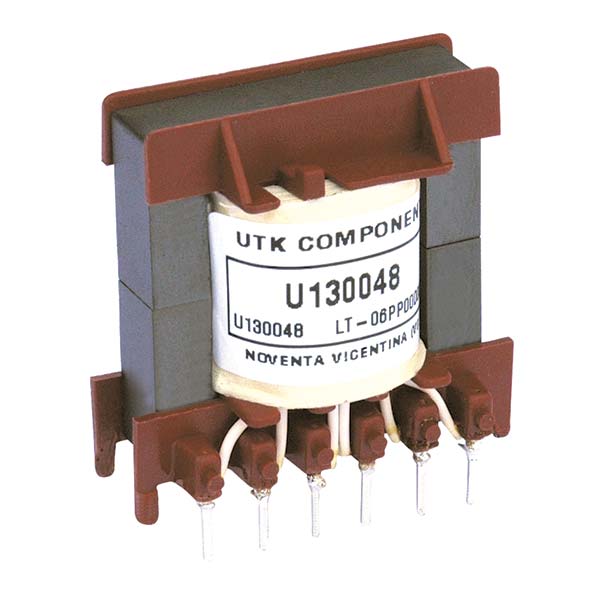

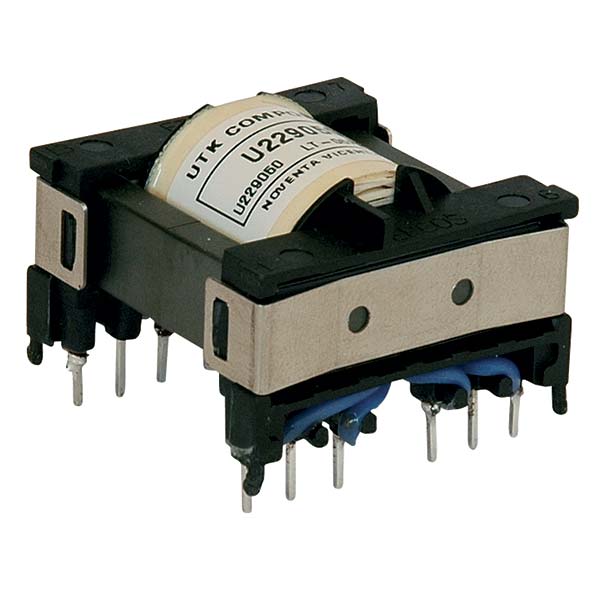

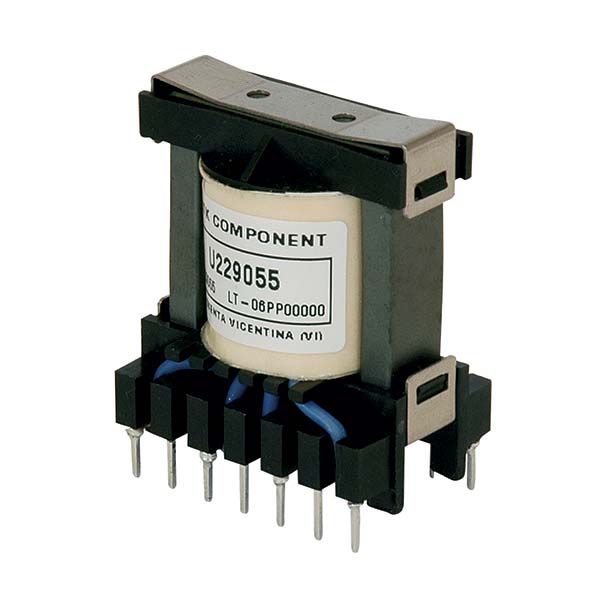

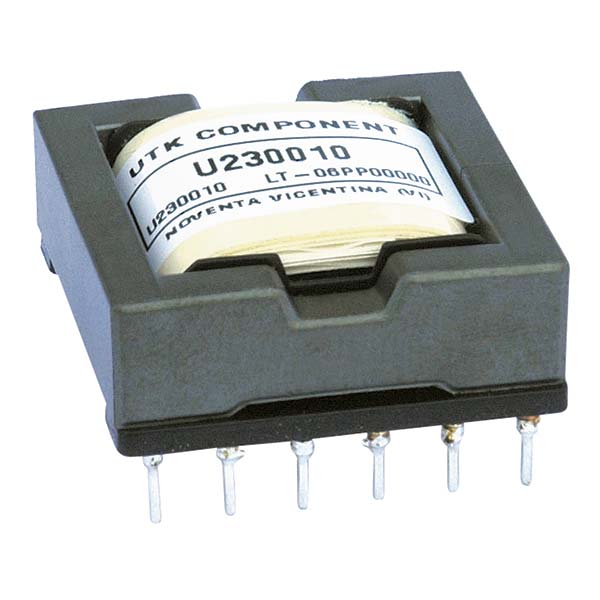

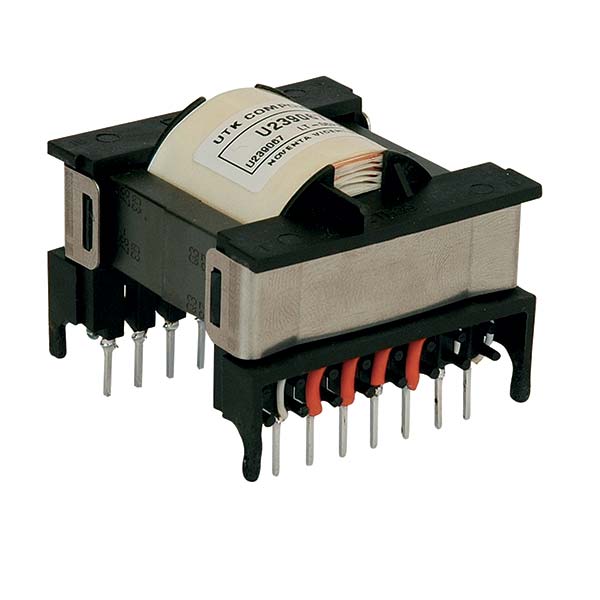

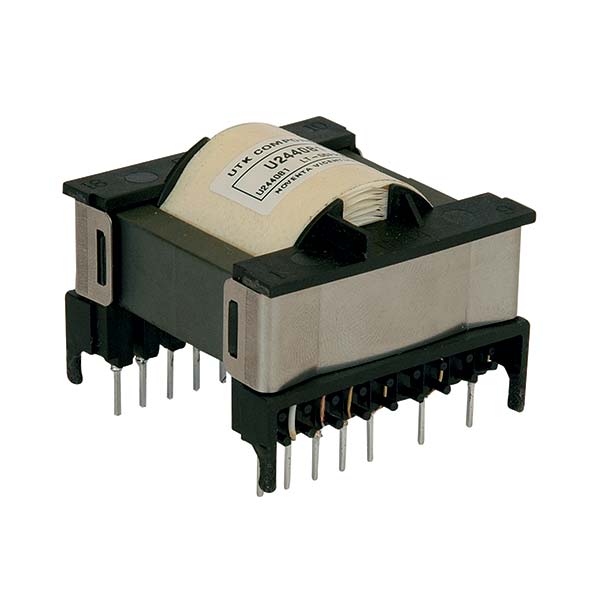

Low power switch mode transformers

Technical description

If linear regulators are still predominant in low power applications (lower than 10W), where no high efficiency, low weight or volume are required, the switch mode power supply circuits have become more and more popular in the last years thanks to the many advantages they offer and to the wide availability and application of single chip control circuits at a low cost. The reduction of the weight and dimensions, the higher efficiency and the lower thermal dissipation bring to an almost unavoidable utilisation of switching circuits in portable battery applications and generally in all applications where particularly restricted weights and dimensions are required for powers up to few hundreds Watts. Other applications, becoming more and more popular, include small standby power supplies and off-line switching circuits for electronic PCBs. The most commonly used circuits topologies for such applications include flyback, forward and push- pull, which provide galvanic insulation from the mains, availability of multiple outputs and powers till few hundreds Watts.

UTK produces transformers for low power switching power supplies according to the customer requirements, using standard configurations and well established methodologies to guarantee the high quality of the result. UTK can also provide qualified technical support in the design phase of the transformer, offering its competence in the selection of the materials and the most suitable production techniques.

Transformers for single chip switching converters are also available.

- National Semiconductor SIMPLE SWITCHER

- ST Microelectronics VIPER 50/100

- Power Integrations TOPSWITCH e TINYSWITCH

UTK Component switching transformers have the following characteristics.

- Compact construction. They are vacuum-filled and encapsulated in plastic box made with self extinguis- hing material UL94-HB, suitable for the application on high density PCBs.

- Availability in a standard temperature range ( 0+80°) or an extended range

- Multiple secondary windings

- Safe and reliable galvanic insulation

- Output power up to 200/300W

- Working frequency up to 500KHz

UTK Component controls closely the production during the process and at the end of it, granting the quality and reliability of the product. The carried out tests include:

- Visual inspection

- Pinout and polarity check

- Value of the reference parameters

- Dielectric strength

Core selection

In the following we give a table to help the designer in the core selection phase, showing the theoretical power output of a switching stage depending on the circuit topo- logy and working frequency. Actual values may differ from the theoretical values since other factors, for exam- ple the number of the secondary windings, working vol- tages, circuit details, temperature rise limits, etc, are not taken into consideration.